SCM L'invincibile TI 7 Tilting Spindle Shaper

Have questions? Give us a call at 260-637-0054.

- Freight included in price*

- In stock as of 4.10.24

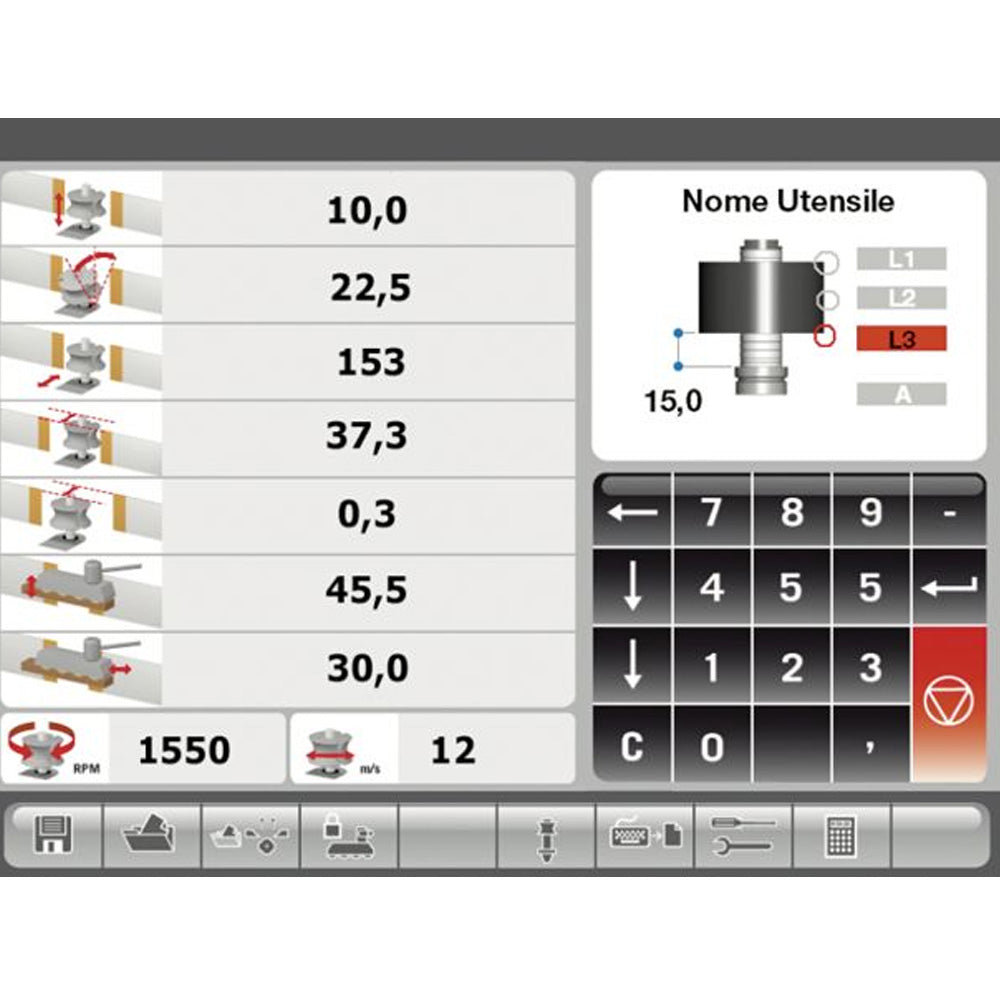

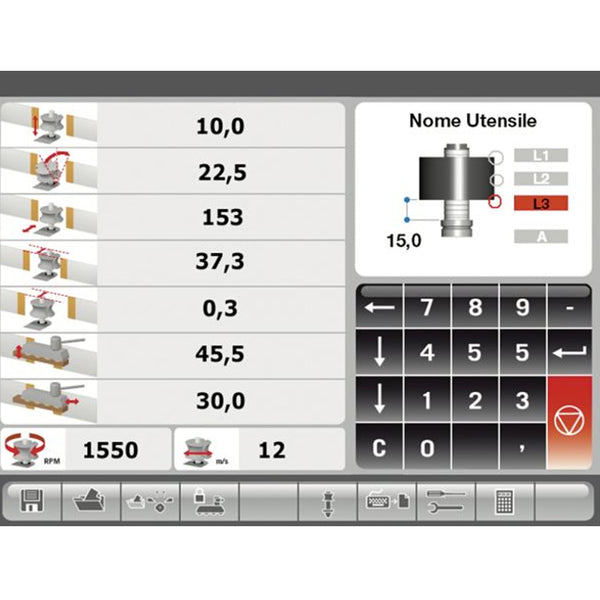

The L’invincibile TI 7 is the most technologically advanced shaper being sold today. It is a tilting spindle CNC machining center with quick change HSK tooling. With the patented fulcrum point for tilted movement, there is no adjustment or electrical compensation necessary for the vertical spindle position or the fence position. Additionally, the L’invincibile TI 7 works in conjunction with the HSK 63B tool holder and the EASY TOUCH interface to read your tool profile. With that kind of technology, this shaper is more like a CNC work-center!

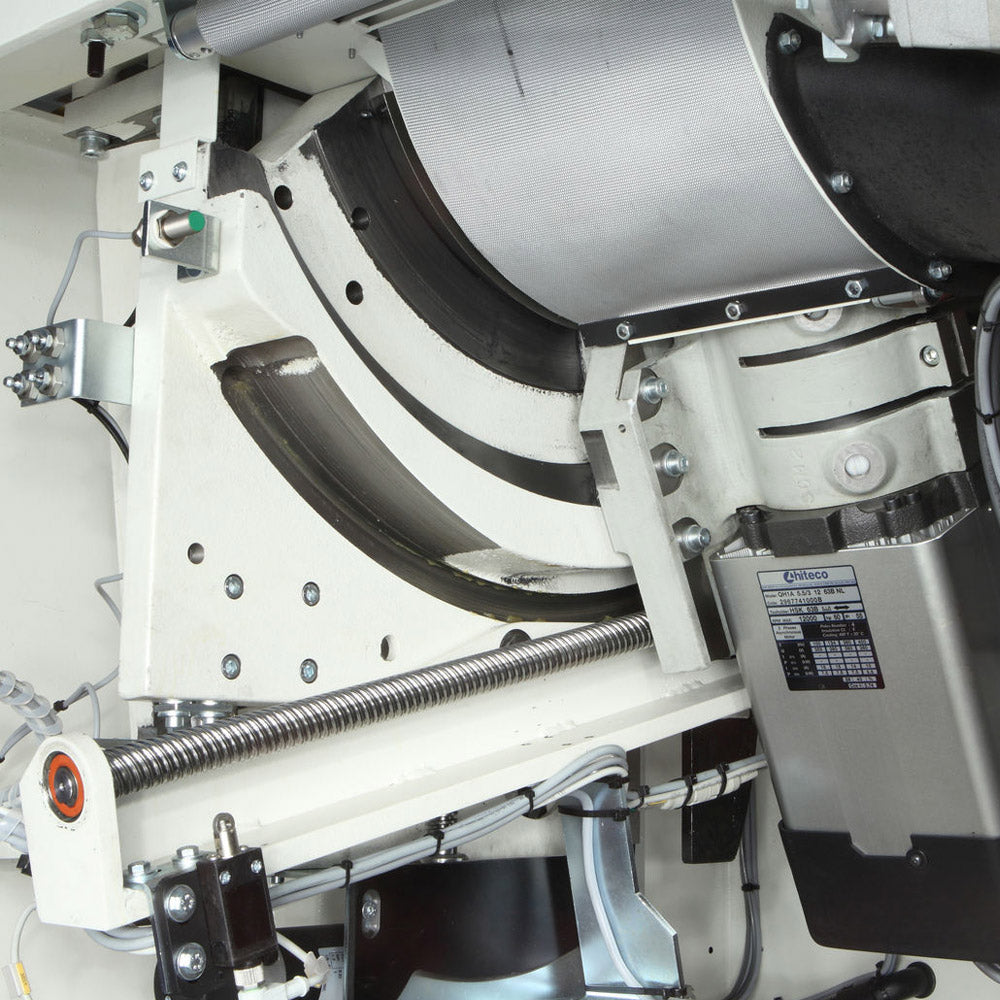

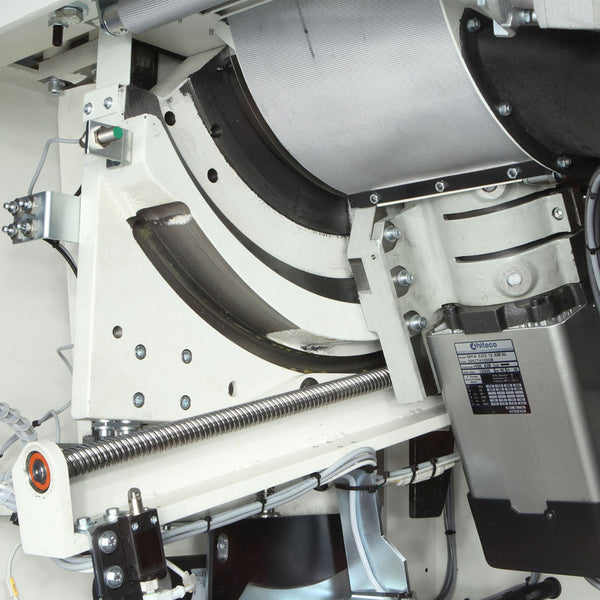

If you could turn a combat tank into a shaper, this would be the outcome. The TI 7 is a tilting arbor shaper like nothing you’ve ever seen. The dovetail trunnions are machined to extremely tight tolerances to ensure perfect angular positioning. Their large size ensures rigidity under load. Ball screw movements are used for the precise positioning of all machine axes. Prismatic guides keep linear movement perfectly straight. They are the standard in most CNC machinery due to their precision, reliability, and reduced maintenance needs. This is a patented tilt system with a zero fulcrum point.

The use of HSK 63B tool holders allows you to share tooling with other CNC equipment making this shaper the perfect platform for backing up the machines. Also featured is the Auto tool detection. This feature allows the programmer to recognize what tool has been installed on the shaper, via the spindle, and will indicate the programs associated with that tool, the maximum speed for that tool, and the maximum vertical stroke among other useful information. The spindles are engineered to handle a tool up to 40lbs.

The “Flex” Fence enables the user to quickly change to different types of fences, use the tenoning table, or to change dust hoods. It is guaranteed to remain square due to its linear guides and alignment pin. This system is fully automated thru the controller and will easily save hours of set up time. Also, the fence has the ability to move behind the spindle for routing work.

With a sectioned table there is no longer any wasted time searching for that correct table ring to fit your cutterhead. This table design has been used on SCM’s Superset moulders and the technology has been transferred to our shapers. The sectioned table position is automated by the Vanguard controller based on the tool diameter in the program.

One thing that can degrade the quality of finish from a shaper is the vibration transmitted from the spindle to the cutter. Minimizing vibration is even more critical when cutting tall profiles or using stacked tooling. SCM Group ensures maximum quality in its shapers by using a liquid cooled direct drive electro spindle assembly whereby the increased mass of the spindle absorbs vibrations and eliminates whipping action at the top of the spindle.

Features

- 7 + Axis integrated touch screen control over:

- Spindle speed, height & angle, fence infeed & out- feed sectioned table, feeder support vert. & horiz.

- Program storage for up to 999 programs

- Automatic Tool Detection System with mobile electromagnetic readout to identify the tool on the machine with reference to the detected tool

- 12hp electrospindle with maximum power available starting at 3000 rpm

- Side cast-iron extension tables, and front telescopic bar (“LL” version)

- Inverter control of electrospindle with range from 900 to 10,000 rpm and electronic brake

- Pneumatic HSK B tool change system with air blower system for clean contact surfaces, and safety sensors

- for tool change operation monitoring: spindle rotation, tool taper lock go / no-go sensor

- (5) HSK B 63 spindles 1-1/4" diameter with tooling cart

- Automatic tooling detection

- Spindle vertical movement on two precision linear guides, and tilt movement on precision arch-formed

- Dovetail trunnion through recirculating ball screw drives

- Flex profiling fence system with 205mm stroke referenced to the center of the spindle shaft, with movement on two linear guides by recirculating ball screw

- Fence includes the ability to stroke behind spindle

- Spindle tilt angle from +45° to - 45° with maximum possible tool projection through angle range

- Upper mobile control panel

- Cope attachment with 500 mm stroke including miter gauge and clamp

- Fast: sectional table to adjust for tool diameter

- Powered cross support mount for feeder with readout

- Aluminum fences

- Magnetic starter with overload protection

- Low tension circuit (110v by transformer)

Specs

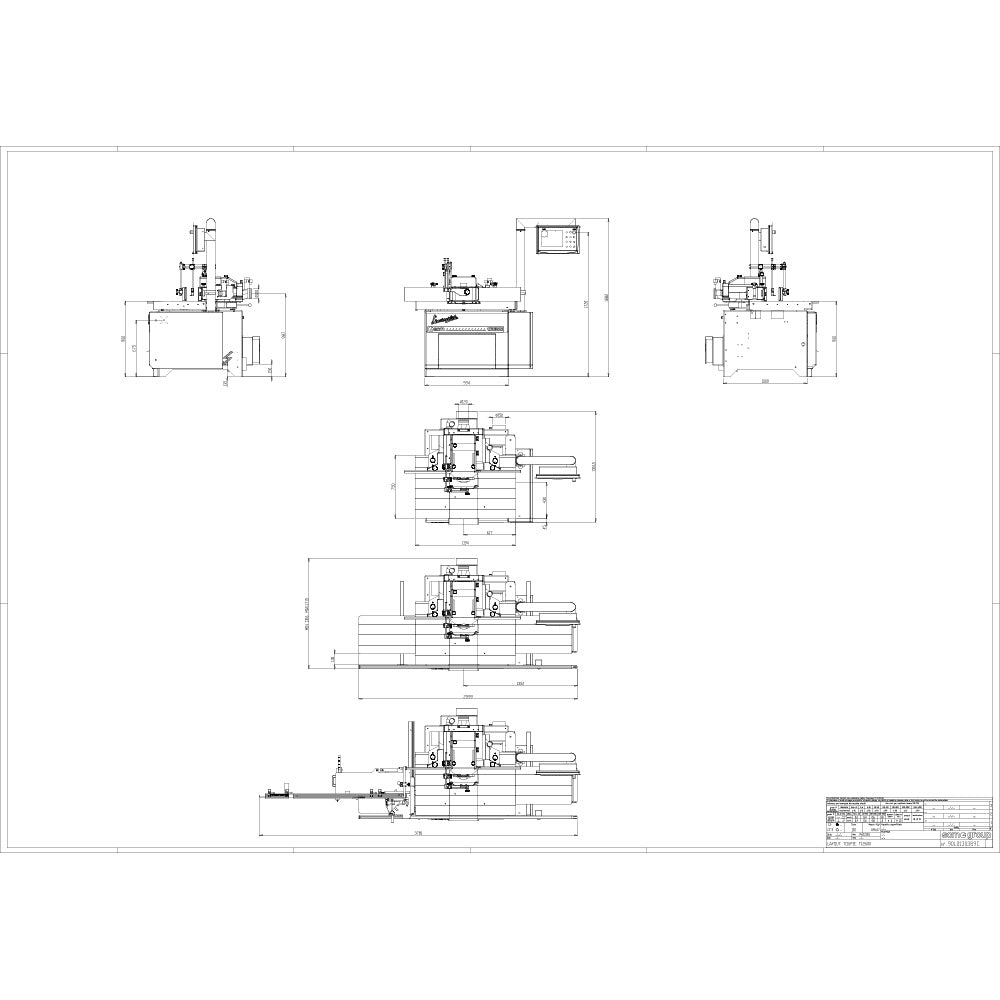

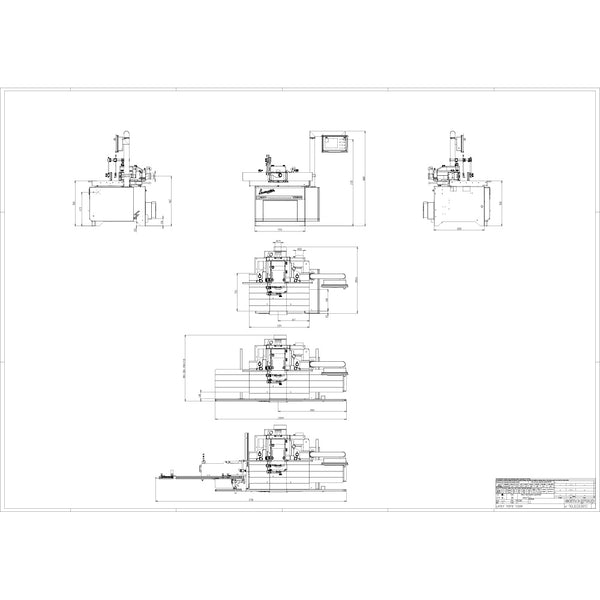

Table Dimensions: 48" x 29.5" (1,194 x 750 mm)

Table Height: 36" (900 mm)

Working Height of Spindle (under the nut): 5.5" (140 mm)

Spindle Tilting: 0 to 45°, 0 to -10°

Max. Tool Diameter w/ Profile Fence: 10"

Max. Tool Dia. Retractable Under Table: 12" x 2.9"

Spindle Speeds: 900 to 10,000 RPM

Dust Outlet on Fence and and Rear Base: 120 mm each

Overall Dimensions (L x W x H): 98" x 29" x 41"

Electrical Requirements: 45 amps @ 230v

Min. Working Air Pressure: 88 PSI

Dust Extraction: 680 CFM x 2

*Shipping

Please note: Items being shipped to extremely remote areas or areas with limited delivery access (such as islands only accessible by ferry) may incur additional shipping or freight fees. If your order requires any additional fees other than what is already included in the price, you will be contacted before those fees are applied and before your item ships. This is rare and will not apply to most orders.